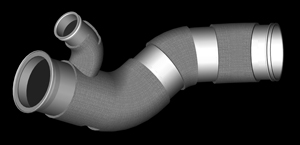

Tube Bending Engineering

For 57 years, Precision Tube Bending’s engineering expertise has kept pace with state-of-the-art design software applications. Equally competent with yesterday’s “Length-Rotation-Angle” (LRA) data or “XYZ” coordinate data; today we are experts with the industry’s leading CAD/CAM systems software, and can read nearly all digital electronic files.

For 57 years, Precision Tube Bending’s engineering expertise has kept pace with state-of-the-art design software applications. Equally competent with yesterday’s “Length-Rotation-Angle” (LRA) data or “XYZ” coordinate data; today we are experts with the industry’s leading CAD/CAM systems software, and can read nearly all digital electronic files.

Precision Tube Bending is a Customer / Proprietary Systems Interfaced company certified as a Digital Product Definition (DPD) / Model Based Definition (MBD) classified site. From engineering to inspection, your electronic data integrity is assured through “Digital Validation Compliance software”. Following our standard protocols, your 3D geometry files are placed in a secure internal digital filing system. This information is then used for design, manufacturing and inspection.

Our engineering team is your expert resource for all types of aircraft tube fabrication and aerospace tube fabrication. Utilizing our vast experience in process specifications; our manufacturing planning is cross checked with our quality engineers to assure a comprehensive review and configuration compliance with your contract.

Relating to Digital Product Definition (DPD), PTB is proficient in reading the following file extension formats:

- .model (CATIA V4)

- CATProduct (CATIA V5)

- .CATPart (CATIA V5)

- .ckd (KeyCreator)

- .Iges / .Igs (Universal)

- .prt (Unigraphics)

- .prt (ProEngineer)

- .dwg (Auto CAD)

- .dxf (Auto CAD)

- .step (Universal)

- .x_t (Parasolid)

- .sw (SolidWorks)